Adaptive Multi-Zone IoT Security Framework for Smart Factory Systems

By Anikait Panigrahi, Barshan Mondal, and Krishnan V Namboothiri

Department of Electronics and Communication Engineering

Amrita Vishwa Vidyapeetham, Amritapuri Campus

In today’s rapidly evolving industrial landscape, the integration of IoT technologies in smart factories has become crucial for achieving Industry 4.0 standards. This project implements a comprehensive smart factory network simulation using Cisco Packet Tracer, integrating advanced wireless technologies and IoT/IoE solutions for industrial environments.

Architecture Overview

Three-Layer Architecture

Our framework follows a robust three-layer architecture designed for scalability and reliability:

Infrastructure Layer

├── Core network backbone

├── Wireless routers and switches

└── Central servers

Communication Layer

├── Wi-Fi 6 for high-speed data

├── Mesh networking for redundancy

└── Private LTE for critical operations

Application Layer

├── IoT sensors and actuators

├── Edge computing nodes

└── User interfaces

Three-layer architecture of the smart factory IoT security framework.

Three-layer architecture of the smart factory IoT security framework.

Key Features

- Advanced Wireless Technologies: Wi-Fi 6, mesh networking, and private LTE implementation

- Comprehensive IoT Integration: Sensors, actuators, and controllers for real-time monitoring

- Multi-Protocol Support: MQTT, Zigbee, HTTP/HTTPS protocols

- Edge Computing: Local data processing for reduced latency

- Predictive Maintenance: Real-time analytics for equipment optimization

- Scalable Architecture: Modular design supporting gradual deployment

Technical Implementation

Network Infrastructure Setup

1. Core Network Configuration

- Deploy wireless routers and managed switches

- Configure DHCP services for automatic IP assignment

- Implement VLAN segmentation for traffic isolation

2. Server Configuration

- Set up MQTT broker for IoT device communication

- Install Node-RED for visual programming and workflow automation

- Configure database servers for historical and real-time data storage

3. IoT Device Deployment

- Deploy sensors for temperature, pressure, vibration monitoring

- Configure actuators with safety interlocks

- Establish edge computing nodes for local data processing

Protocol Implementation

- MQTT: Lightweight messaging for IoT device communication

- Zigbee: Low-power mesh networking for sensor networks

- HTTP/HTTPS: Web-based interfaces and administrative functions

Wireless Solutions

- Wi-Fi 6: High-speed, low-latency connectivity for multiple simultaneous devices

- Mesh Networking: Redundant connectivity paths eliminating dead zones

- Private LTE: Dedicated wireless infrastructure for critical manufacturing processes

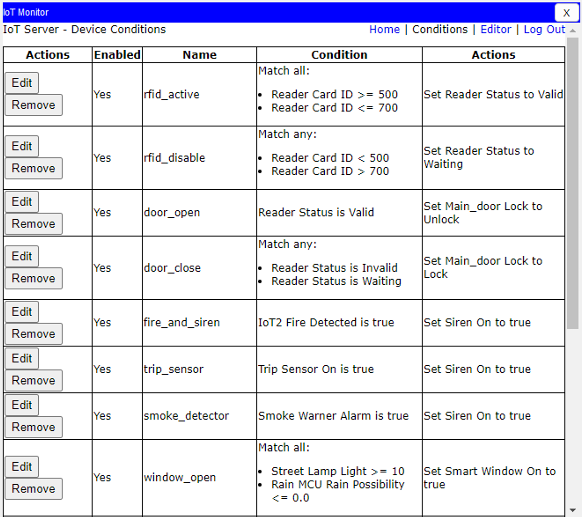

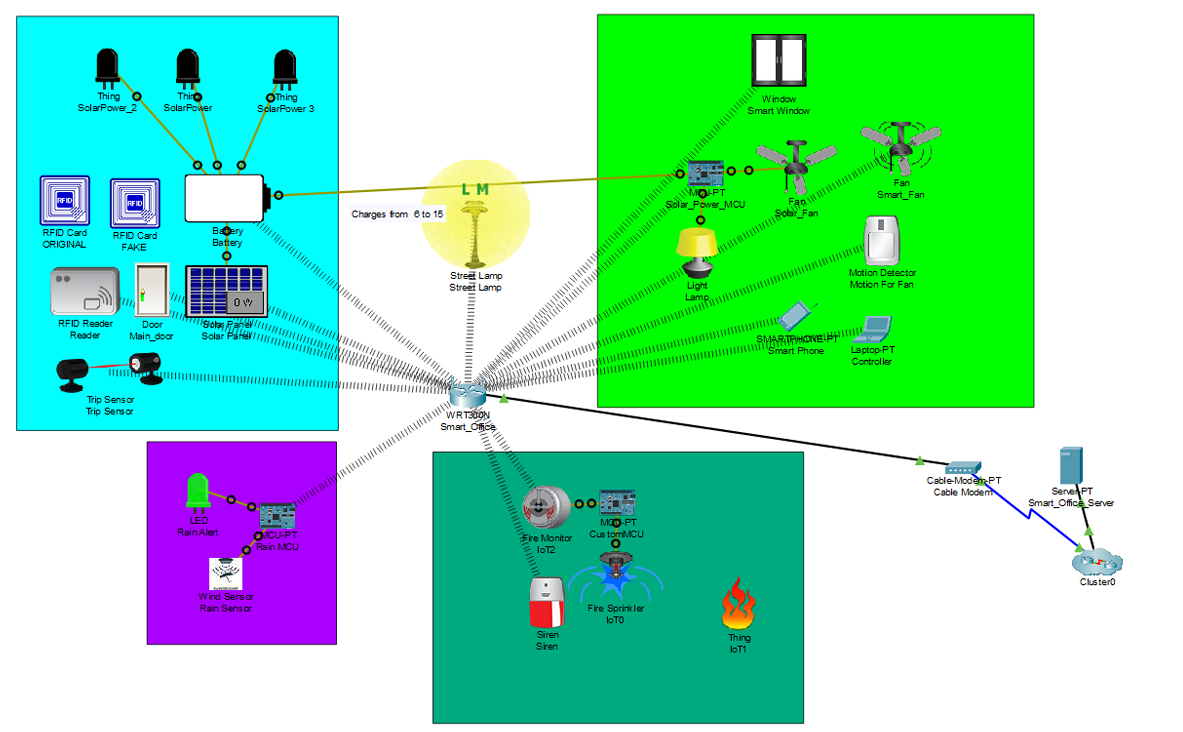

Network topology showing wireless connectivity and IoT device deployment.

Network topology showing wireless connectivity and IoT device deployment.

Performance Metrics

Network Performance

- Latency: <10ms for real-time control applications

- Throughput: Supports multiple concurrent IoT data streams

- Coverage: Complete signal coverage across factory floor

- Reliability: 99.9% uptime with redundant connectivity

IoT Device Performance

- Data Accuracy: Within acceptable tolerance ranges

- Response Time: Real-time control loop requirements met

- Energy Efficiency: Optimized power consumption for battery-powered devices

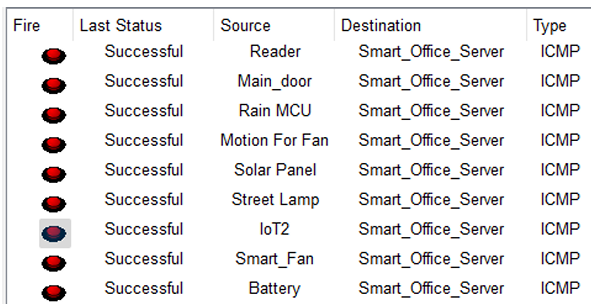

Real-time performance metrics showing latency, throughput, and device status.

Real-time performance metrics showing latency, throughput, and device status.

Testing and Validation

Testing Procedures

- Functional Testing: Verify all system components operate per specifications

- Integration Testing: Ensure interoperability between different protocols

- Performance Testing: Evaluate system behavior under various load conditions

- Security Testing: Validate wireless authentication and data encryption

Validation Results

- Real-time data collection and processing

- Predictive maintenance capabilities

- Network performance meets Industry 4.0 requirements

- Complete wireless coverage validation

- IoT device integration verification

Server configuration and IoT monitoring dashboard showing system validation and performance benchmarks.

Server configuration and IoT monitoring dashboard showing system validation and performance benchmarks.

Security Framework

Multi-Zone Security Implementation

Our adaptive security framework implements a sophisticated multi-zone approach:

- VLAN Segmentation: Network divided into security zones

- Zone-Based Access Control: Different security levels per zone

- Threat Isolation: Compromised zones isolated automatically

- Real-time Monitoring: Continuous security assessment

Security Features

- Adaptive Security: Security policies change based on zone and threat level

- Real-time Threat Detection: Continuous monitoring for security breaches

- Automatic Response: Immediate isolation of compromised devices

- Multi-Protocol Security: Security across MQTT, Zigbee, and HTTP/HTTPS

Benefits

- Real-time Monitoring: Immediate response to production anomalies

- Predictive Maintenance: Reduced unplanned downtime

- Scalable Deployment: Gradual implementation based on resources

- Enhanced Visibility: Comprehensive production process insights

- Cost Efficiency: Wireless connectivity reduces cabling requirements

Future Enhancements

- Advanced security implementations

- 5G technology integration

- Machine learning algorithms for enhanced predictive analytics

- Extended IoT device library support

- Cloud integration capabilities

Project Structure

smart-factory-iot-security/

├── simulations/

│ ├── smart-factory-network.pkt

│ ├── iot-device-configs/

│ └── network-topologies/

├── documentation/

│ ├── network-design.md

│ ├── protocol-analysis.md

│ └── performance-reports/

├── scripts/

│ ├── device-configuration/

│ └── monitoring-tools/

└── README.md

⚙️ Technical Requirements

Prerequisites

- Cisco Packet Tracer (Latest Version)

- Basic networking knowledge

- Understanding of IoT protocols

Hardware Requirements

- Wireless routers supporting Wi-Fi 6

- Managed switches with VLAN capabilities

- IoT sensors and actuators

- Edge computing nodes

- Central servers for data processing

Software Requirements

- MQTT broker implementation

- Node-RED for workflow automation

- Database management system

- Security monitoring tools

- Network management software

Key Takeaways

This project demonstrates the power of integrating multiple wireless technologies and IoT protocols in a unified smart factory environment. The adaptive multi-zone security framework ensures robust protection while maintaining operational efficiency.

The combination of Wi-Fi 6, mesh networking, and private LTE creates a resilient communication infrastructure that can handle the demanding requirements of modern manufacturing processes.

Key Insight: The fusion of multiple wireless technologies with adaptive security creates a more robust smart factory system than any single approach alone.

Contact Information

- Anikait Panigrahi: anikait05@gmail.com

- Barshan Mondal: barshan2004@gmail.com

- Krishnan V Namboothiri: krishnanvezhaofficial@gmail.com

This project is licensed under the MIT License.